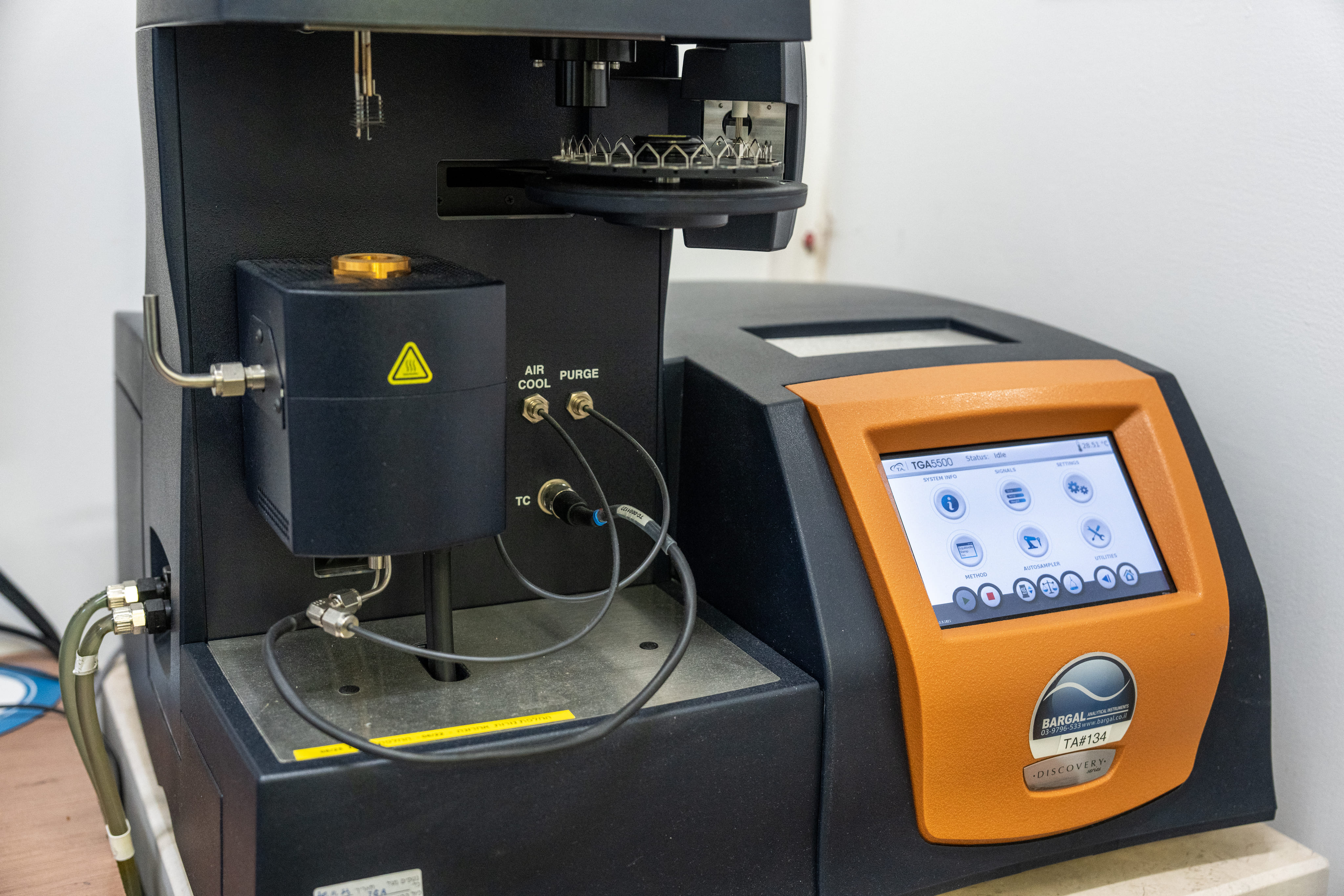

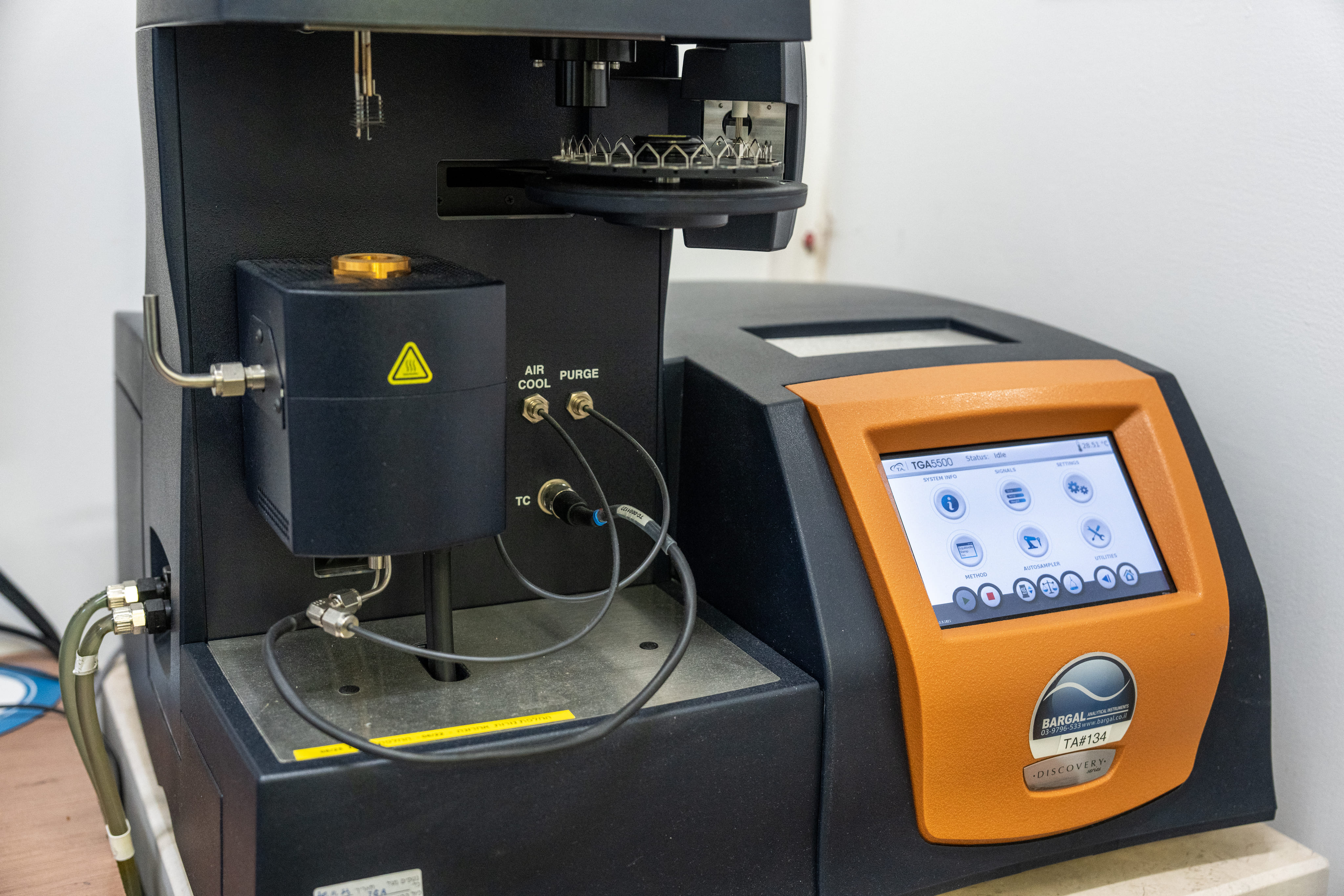

TGA – MTGA

Thermogravimetric Analysis - measures material thermal decomposition & stability.

Modulated mode calculates the activation energy provides lifetime assessment.

Reach out to our experts and start today!

Thermogravimetric Analysis - measures material thermal decomposition & stability.

Modulated mode calculates the activation energy provides lifetime assessment.

Simulates material durability under accelerated UVA and UVB radiation, heat and moisture exposure.

Fourier Transform Infra-Red light vibrates the material chemical bonds and identifies the chemical composition (by ATR or Transmission mode).

Optical microscopy comprehensive analysis offers failure investigation, contaminants, and dispersion evaluation.

Filter test analysis developed by Netafim determines various types of contamination.

Differential Scanning Calorimeter - analyzes thermal properties such as crystallinity percentage, melting points and Oxidation Induction Time.

Evaluates the mechanical properties of a specimen, such as tensile strength, elongation and modulus of elasticity, to determine its performance under applied stress.

Measures the absolute amount of moisture content using Karl Fischer reagent.

Melt Flow Index - assesses the flow properties and processability of molten polymer.

Environmental Stress Crack Resistance - evaluates a material's ability to withstand cracking when exposed to mechanical stress and environmental factors.

Measures carbon black, ash content and material impurities.

Prepares samples and sheets for testing and examination.

Climate samples for relaxation and stress release.

Measures hardness to evaluate flexibility and structural resilience.

Blown thin films for gel count analyses and samples preparation for weathering and quality testing.

Measures material density

Simulates material durability under accelerated full-spectrum sunlight, heat and moisture exposure.

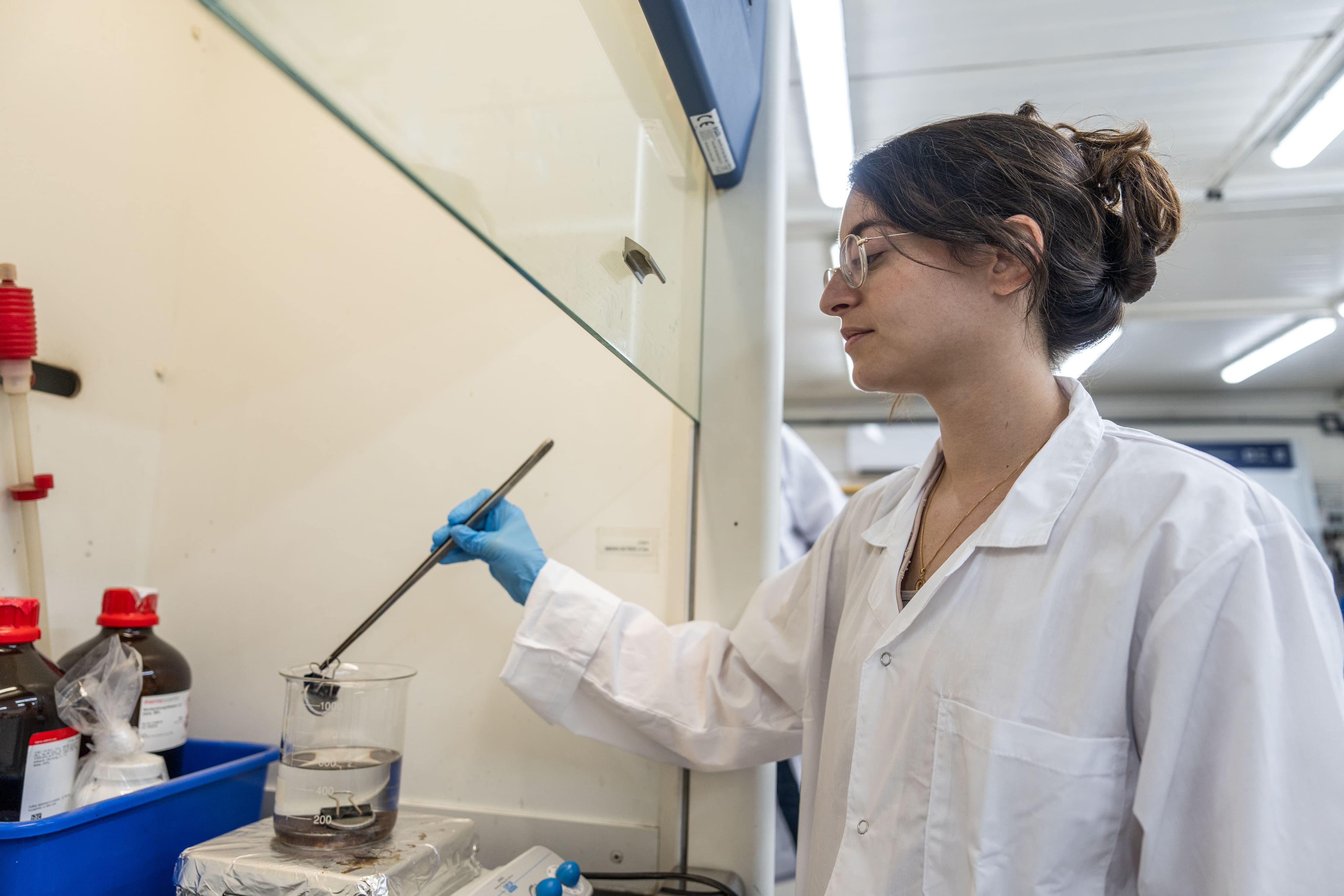

We develop tailored tests to address the specific needs of each product, ensuring accuracy and reliable results.

Extensive knowledge and experience are used to conduct comprehensive testing for operational and R&D purposes.

Our expert team accompanies the production process at every stage providing quick, efficient solutions to any problems that may arise during and after production.

Performing thorough testing to ensure all materials and products meet the highest standards and requirements.

Our thorough analyses make sure that our products are crafted from the highest-quality reliable materials, with the accurate production process.

Reach out to our experts and start today!